Business Imprint

10 Ways to Prevent Downtime in Manufacturing

Manufacturing downtime can be detrimental to any business, leading to lost revenue and decreased productivity. While unplanned downtime is inevitable in any manufacturing environment, proactive measures can be taken to reduce the occurrence of this costly problem.

This article outlines 10 key steps that can help to prevent downtime in manufacturing processes, such as preventive maintenance, predictive analytics, and better inventory management. By taking these steps, manufacturers can reduce the amount of unscheduled downtime and keep their businesses running smoothly.

What Is a Downtime in Manufacturing

In manufacturing, downtime is a period when machinery or equipment is not operating due to unplanned repair and maintenance or other disruptions. This can include anything from unexpected machine breakdowns and system failure to supply chain issues or human errors.

Unscheduled downtime can have significant financial implications for any business, leading to lost production time and decreased efficiency. It can result in additional costs due to overtime and an inability to meet customer demand, leading to decreased profitability and revenue.

While some downtime is inevitable, businesses must take proactive measures to reduce the amount of unscheduled downtime experienced.

Consequences of Downtime in Manufacturing

Downtime in manufacturing can have several consequences for businesses, including the following:

Financial Losses and Decreased Customer Satisfaction

Unscheduled downtime leads to direct financial losses due to decreased production time and lowered efficiency.

Additional costs can also be incurred due to paying for overtime, increased energy consumption, and the need for additional resources. This downtime can also lead to customer dissatisfaction as orders cannot be fulfilled promptly or at all.

Decreased customer satisfaction can cause long-term effects, such as a drop in repeat business or negative reviews.

Reduced Quality of Products and Services

Downtime can also lead to a decreased quality of products and services due to mechanical issues or human errors resulting from time pressure or lack of training. This can have severe repercussions for any business, leading to product defects, customer complaints, and additional costs associated with recalls or warranty repairs.

Increased Risk of Injury and Accidents

In some cases, unplanned downtime can increase the risk of injury or accidents due to a lack of maintenance or poor safety protocols. This is especially true in environments where machinery is operated by untrained personnel or in hazardous conditions.

Inability to Adapt to Changes in the Market

Downtime can also prevent businesses from being able to respond to changes in the market, such as new customer demands or technological advances. This can lead to lost opportunities and decreased competitiveness, which can have long-term implications for any business.

Stress and Overwork for Employees

Additionally, unplanned downtime can cause stress and overwork for employees due to the need to work overtime or find ways to compensate for lost production time. This can lead to higher employee turnover rates and decreased morale, further impacting the business’s productivity.

Businesses can minimize these consequences by taking proactive steps to reduce downtime and improve their overall efficiency.

10 Steps to Prevent Downtime in Manufacturing

The following 10 steps can help reduce the amount of unscheduled downtime experienced by manufacturers:

1. Perform Regular Maintenance

Proper maintenance is essential for keeping machinery functioning properly and avoiding unplanned downtime. This includes regularly scheduled maintenance and inspections to identify potential issues before they become serious problems.

2. Implement a Predictive Maintenance Program

Predictive maintenance can help manufacturers anticipate when machinery or equipment is likely to fail, allowing them to take steps to prevent downtime. This program utilizes data gathered from sensors and machine learning to identify potential problems before they become significant issues.

3. Invest in Quality Parts and Equipment

Investing in high-quality parts and equipment can help minimize unscheduled downtime by minimizing the chances of malfunction or breakdown. It’s important to choose parts from reliable suppliers designed for the intended use and have a good track record of reliability.

4. Train Employees Properly

Proper training of employees can help reduce downtime by ensuring they are familiar with the machinery they are operating and have the necessary skills to respond quickly in the event of a breakdown. It’s also essential to provide ongoing refresher courses or updates on the new technology so that employees stay up-to-date with their skills and knowledge.

5. Install Automation Systems

Professional downtime tracking software can reduce downtime by automating processes prone to human error or incredibly tedious for employees. This can include features such as automated scheduling of maintenance tasks, monitoring equipment performance, and safety protocols.

6. Utilize Remote Monitoring

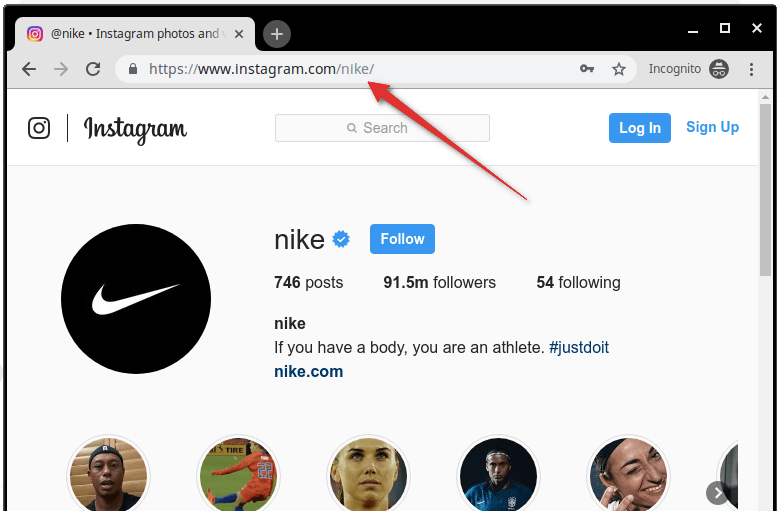

Remote monitoring systems allow businesses to monitor their equipment and operations from anywhere in the world. This can reduce downtime by providing real-time alerts of any issues, allowing faster responses and more efficient problem resolution.

7. Utilize Data Analytics

Data analytics tools can identify trends or patterns in operational data that can help businesses anticipate issues before they become serious problems. This can be especially effective with predictive maintenance, as it allows for more accurate predictions and earlier detection of potential downtime.

8. Analyze the Work Environment

Analyzing the work environment to identify any potential safety hazards or areas of improvement can help reduce downtime by eliminating or reducing the chance of accidents and injuries. This includes keeping the workspace clean and organized, maintaining adequate lighting, and ensuring proper ventilation.

9. Utilize Spare Parts

Spare parts can reduce downtime by allowing businesses to quickly replace malfunctioning components without waiting for new parts to arrive. It’s important to have a comprehensive inventory of spare parts for all machinery and equipment and adequate storage space for them.

10. Have a Contingency Plan

A contingency plan can help reduce downtime by providing clear procedures that should be followed in an emergency. This plan should include steps such as identifying the source of the problem, notifying personnel, and taking steps to minimize any further disruption.

By implementing these strategies, manufacturers can significantly reduce their risk of unscheduled downtime and ensure that operations run smoothly and efficiently.

Final Thought

Reducing downtime in manufacturing requires a comprehensive approach that includes investing in quality parts and equipment, training employees properly, utilizing automation systems, remote monitoring solutions, and data analytics tools, analyzing the work environment, stocking spare parts, and having a contingency plan.

By taking these steps and implementing the above mentioned strategies, manufacturers can ensure that their operations run smoothly and efficiently, helping maintain their competitive edge.

-

Cyber Risk Management4 days ago

Cyber Risk Management4 days agoHow Much Does a Hosting Server Cost Per User for an App?

-

Outsourcing Development4 days ago

Outsourcing Development4 days agoAll you need to know about Offshore Staff Augmentation

-

Software Development4 days ago

Software Development4 days agoThings to consider before starting a Retail Software Development

-

Grow Your Business3 days ago

Grow Your Business3 days agoThe Average Size of Home Office: A Perfect Workspace

-

Solution Review3 days ago

Top 10 Best Fake ID Websites [OnlyFake?]

-

Business Imprint4 days ago

How Gaming Technologies are Transforming the Entertainment Industry

-

Gaming Technologies2 days ago

Gaming Technologies2 days agoHow to Set Up Text-to-Speech for Channel Points on Twitch