Business Imprint

What is Contract Manufacturing and Toll Manufacturing?

Toll manufacturing and contract manufacturing are two ways to do business for large and small businesses. What are they and how can they differ?

Manufacturing success can be achieved in many ways. Some companies begin from scratch and manufacture their products in-house right away.

Some people produce a portion of their goods, while others buy partially processed materials or sub-assemblies.

Some companies use the facilities of another company to manufacture entire product lines, either as a transition into in-house production or as part of their core business model.

The latter refers to those who produce their products through another entity.

Contract manufacturing is where a company enters into a contract with a manufacturer to produce certain products for their parent company.

This arrangement is also known as white label manufacturing or private manufacturing. It can be found in many industries.

One example is food production, where the name-brand food labels produce their product lines while using the same equipment and sometimes the same raw materials to create private label foodstuffs. These food chains often sell both the in-store and the name-brand products on the shelves.

Store-brand and name-brand products are often produced at the same facilities.

Why companies use contract manufacturing?

Contract manufacturing is used by companies for many reasons.

Contract manufacturing, which is a capital-intensive industry, allows companies to concentrate on product design, marketing and sales while reducing manufacturing costs to a fixed, less variable cost that is easier manageable.

Companies can concentrate on their core competencies without the need to purchase capital equipment. This allows them to grow their product lines and avoid having to worry about financing.

Contract Manufacturing can also be used to bridge the transition to in-house production.

A company may decide to make some subassemblies or products at a contract manufacturer, depending on its capital cost. This is to ensure that production can continue until the capital equipment is purchased and commissioned in-house.

As the parent company is able to afford a “pay as you go” model, this allows for incremental growth without incurring high levels of debt.

Contract manufacturing is a good option for companies that have seasonal, highly cyclical production. However, it is not feasible to invest in additional equipment, but extra production is necessary for existing product lines.

This allows the parent company to adjust to its own production cycle after the season is over. It also gives them the ability to manage cost, raw material inventory, and other operations on a more variable basis.

Ice cream is a great example of a product that sees increased production in the summertime.

Contract Manufacturing Risques

However, contract manufacturing comes with risks.

There are some risks involved in manufacturing with an outsourced third-party manufacturer.

- Geographical Considerations – Third-party manufacturers might be restricted by the laws of their country from shipping to certain locations, leaving the parent company without a way to ship their goods.

- Limited logistics – Many contract producers are bulk manufacturers that do not perform well in fulfillment. The parent company will still have to pay for shipping and logistics costs, but may be able to save money on production.

- Quality control – The parent company will be able to lessen the ability to monitor, control and ensure quality from third-party manufacturers than it would with in-house controls.

- Intellectual property – Third-party manufacturers can leak proprietary information to other companies who are producing similar products at lower prices.

Toll Manufacturing

Toll manufacturing is a different process than contract manufacturing. Contract manufacturing is where the manufacturer of the finished goods is responsible for the whole production process.

This includes the procurement raw materials as well as all production stages from beginning to end.

Toll manufacturing is where the parent company supplies the materials and design, while the third-party company processes the raw materials or semifinished goods.

Toll manufacturing is where the parent company controls more than the third-party producer. This is because the parent company supplies and manages the raw materials flow. Toll manufacturing is illustrated by the following:

- Apple/Foxconn – Although everyone is familiar with Apple, not all may be aware of Foxconn. Foxconn is the manufacturer that Apple sends materials to, such as electronic components and housings, glass for screens and LEDs for production of its phones and computers.

- Microsoft/Flextronics – Like Apple, Microsoft partners with Flextronics to produce its finished products, the components of which are supplied by Microsoft.

- Boutique Wineries – Toll Manufacturing isn’t only used by large companies like Apple and Microsoft. Many boutique and small wineries around the globe use mobile manufacturing bottling to bottle and label their wine after it has aged. The winery can keep control of the product and quality, much like Apple.

Toll Manufacturing gives companies greater control than contract manufacturing, and reduces quality control risks.

They can also better manage fulfillment and logistics, and have more control over their proprietary aspects.

Toll manufacturing is often used in the electronics industry.

Contract Manufacturing with ERP/MRP

Third-party manufacturers may also be able to perform contract and toll manufacturing.

These production methods still offer the potential for robust manufacturing ERP systems.

This applies regardless of whether the software’s user is the parent company, or a third-party manufacturer.

Both cases result in the bill-of-materials determining the utility of an MRP System.

A parent company can keep track of all its goods manufactured by third parties through the BOM. This includes routings, inventory usage, and output of finished products.

This allows for quicker resolution of issues when they arise.

Third-party manufacturers can use flexible and agile manufacturing software to take on finished goods manufacturing work from multiple parent companies. They can also manage production flow with precise BOMs, fully costed materials, and controllable labor centers.

These software platforms provide third-party manufacturers with many features, including multi-level BOMs and EDI transmissions. They also allow for labor tracking, shopfloor mobility, engineering change order management and revision and versioning controls.

MRP software is a valuable link between parties involved in contract or toll manufacturing.

Conclusion

While contract manufacturing and toll production are similar methods of production, they can’t be interchangeable.

Contract manufacturing is when a company uses the production facilities of another company from the procurement stage to the emission.

Toll manufacturing is where the parent company supplies the manufacturer raw materials and design while maintaining some control over the production process.

Both cases and both parties would benefit from an MRP Software to make the partnership more transparent and improve many manufacturing processes.

-

Marketing Tips15 hours ago

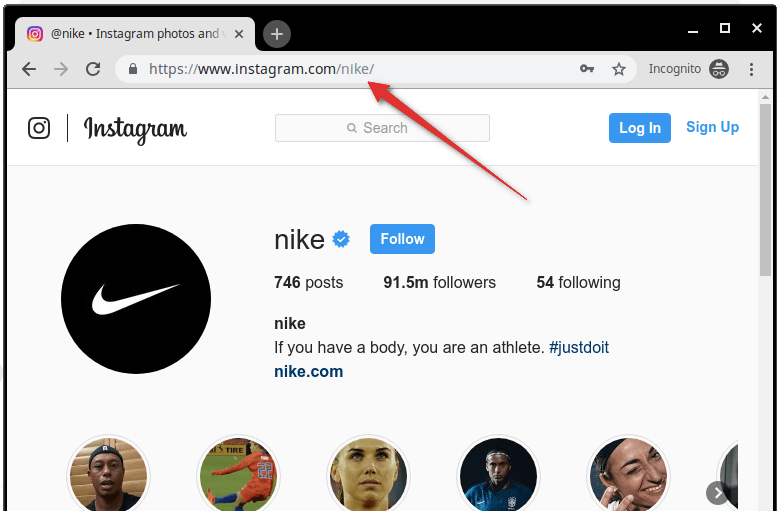

Marketing Tips15 hours agoWhat is my Instagram URL? How to Find & Copy Address [Guide on Desktop or Mobile]

-

Business Imprint2 days ago

Business Imprint2 days agoAbout Apple Employee and Friends&Family Discount in 2024

-

App Development2 days ago

App Development2 days agoHow to Unlist your Phone Number from GetContact

-

News3 days ago

News3 days agoOpen-Source GPT-3/4 LLM Alternatives to Try in 2024

-

Crawling and Scraping3 days ago

Crawling and Scraping3 days agoComparison of Open Source Web Crawlers for Data Mining and Web Scraping: Pros&Cons

-

Grow Your Business15 hours ago

Grow Your Business15 hours agoBest Instagram-like Apps and their Features

-

Grow Your Business3 days ago

Grow Your Business3 days agoHow to Become a Prompt Engineer in 2024

-

Marketing Tips15 hours ago

B2B Instagram Statistics in 2024