Business Imprint

What is Warehouse Automation and Why Implement It

State-of-the-art warehouse automation resembles a well-coordinated dance. Every box and pallet is in its place, moving upon request. Everything is defined and clear, every absence of a necessity alerts specialists who make a reorder. Warehouses of the future — or advanced warehouses that already exist — are designed for maximum efficiency and minimum disruption.

What Is Warehouse Automation and How Does It Work?

Warehouse automation encompasses processes that enable efficient inventory movement in, out and within the warehouse facility with as little human assistance as possible.

The main goal of any automation process, be it for a warehouse, an assembly line, or another place, connected to work, is to eliminate any monotonous physical labor and manual data entry — and reduce human errors that come from people attempting to analyze a large amount of data by themselves.

For warehouse automation, businesses reduce the burden on the workers via establishing a sortation system. Then, items on the sortation line are identified digitally and automatically (usually by using barcodes on the packages), after which each package is directed to an appropriate place in a warehouse. To automate manual data entry, logistics companies use barcodes for NFC, RFID chips, and QR codes, too, while machine learning helps them to, e.g., forecast traffic based on historical data. Automation can be utilized within software warehouse uses: for instance, within solutions for inventory management or fleet management.

Warehouse owners often automate the following processes:

Receiving

The process can be partially or fully automated — facilities can use various devices with integrated sensors and scan the marked packages to note which new items have arrived.

Sorting

When the item is identified upon arrival, it must be cataloged and directed to where it’s supposed to be stored. Sortation lines and systems we’ll talk about later — and other technologies — are used during this process.

Put-away & Picking

When a proper location within a warehouse has been identified for a new item by the sorting system it must be placed there. And when the time comes (the item is needed: for selling, transportation, etc.) — it’s retrieved from there. Conveyors, AS&RS systems, AGVs, vertical lift systems, carousels, and AMRs are used in the automation of put-away and picking processes.

Remember, in the beginning, we said that the state-of-the-art warehouse automation resembles a well-coordinated dance?

All of these systems work in unison, synchronized in perfect rhythm, controlled by a single digital “mind”— an advanced piece of software. This software receives and takes into account information not just from the inventory catalog, but from each sensor of each system, be it a conveyor or one of its miniature helpful robots, AGVs and AMRs. This software, usually connected to warehouse management or inventory management solution, can orchestrate movements of each system’s component to achieve maximum efficiency and avoid collisions and other mishaps.

Replenishment

Items being out-of-stock can happen for various reasons. Over the past couple of years, for instance, the world has seen a component shortage (re: microchips) and shipping delays for various reasons, from the pandemic to the Suez Canal blockage. But those are disruptions businesses have very little control over. Products shouldn’t be out-of-stock, though, because someone forgot to replenish them.

Warehouse management systems track the amount of stock in the facility and upon it reaching the assigned minimum, a replenishment request is automatically created. Remembering things is hard, and well-timed alert systems make everything so much easier. Automation within replenishment also helps avoid overstocking, which helps optimize facility resources, cut maintenance costs, and avoid products reaching their expiration date too early.

Main Warehouse Automation Types

Warehouses differ, and so are their needs. Automation is usually a customizable process that can be presented differently in a warehouse. It can be physical — when machinery moves items around the facility. It can be virtual — when software collects stores and analyzes inventory data.

Let’s talk about physical types of automation and systems that help to adopt it.

Automated storage and retrieval systems (AS&RS)

AS&RS systems are solutions for supply chain management that are capable of automatically placing, moving, and retrieving objects within a facility. A comprehensive approach typically involves integration with warehouse automation software. Software algorithms often also choose the best place for each item: e.g., objects that will remain in the facility longer are situated further from the sorting line and pickup points, compared to items that will be moved briefly after they’re received by a warehouse.

Goods-to-person (GTP) technologies

Such technologies bring stock containers to warehouse workers, eliminating the need for walking around the facility to collect an item. Unlike AS&RS, GTP requires more human involvement — but it’s still very useful, especially in large warehouses.

Pick-to-light systems

Such systems help workers fulfill orders. Often, several items must be delivered from the warehouse to a person or another facility in a single order. A worker scans the order barcode, after which the shelves with particular sets of products are delivered to them by the GTP system, and a small monitor lights up under particular boxes indicating which exact items (and, in some cases, a number of them) must be taken to fulfill the order. Such systems are effective in reducing errors that occur during order assembly.

Sorting systems

Sorting lines are highly effective at quickly identifying and sorting items. How objects are sorted can depend on several factors: what their size is, how long they will be in the warehouse, and what are the storage requirements for containing them (for example, some items might need to be stored in a refrigerated section), etc. Sorting systems are much faster and more accurate than manual sorting.

Warehouse Automation Benefits

Warehouse automation is a comprehensive process that:

- Streamlines Operations

Even small conjunctions, if not immediately solved, can result in an overwhelming issue in logistics. Therefore, whenever dealing with large volumes of items, increasing the speed of warehouse operations with them is of the utmost importance.

- Maximizes warehouse space

Keeping a warehouse at its optimal capacity can help maximize profits received by the facility.

- Lowers operational costs

Labor costs are a vivid example. Having fewer errors can also help eliminate the costs of fixing them.

- Optimizes inventory

Being over- or understocked either strains the resources of a facility or can result in profit loss. Automation allows for optimal inventory levels.

- Fewer injuries

Manual labor can sometimes result in worker injuries. Automating warehouse processes, however, drastically reduces such cases: people don’t have to organize and transport heavy boxes all day by hand.

5 Reasons Why You Need Warehouse Automation

Are you still wondering if automation is worth it? Consider these five factors while performing your cost-benefit analysis for this project:

- Space optimization. Automation helps optimize warehouse space. According to Yale Materials Handling, the optimal capacity used for a warehouse is 85-90% (leaving 10 to 15% of it for when you need to handle an unexpected surge in products/orders volume, like on Christmas).

- Time optimization. After adopting automation, businesses save the time it takes for employees to move around the facility, pick, sort, and move parcels.

- Sustainability. Businesses can reduce their carbon footprint if they automate with the environment in mind. Generally, packages handled automatically need less packaging. Automation can also reduce the number of broken pallets, reducing waste. At the same time, increased accuracy of order filling decreases the number of returns and environmental costs associated with them.

- Better working conditions. After adopting solutions built around automation. employees are left with less labor-intensive duties. No more need to travel great distances every day or lift heavy objects. And as we have mentioned, this also decreases the number of accidents and injuries they might have. Higher levels of job satisfaction can help with employee turnout, which is especially important given the recent labor shortage faced by, as it seems, all industries.

- Higher profits. All of the factors we’ve mentioned above are interlinked, and each of them contributes to a business being more competitive and having higher profits.

To summarize, automation helps make warehouses a true asset for the business. It has many benefits: storage space, employee efficiency, and capacity optimization, as well as operating costs optimization. All of that makes the organization more profitable and the idea of automation — more lucrative, which is why many companies in different fields, from retail to logistics to food industries, are considering implementing it within their warehouses.

-

Marketing Tips3 days ago

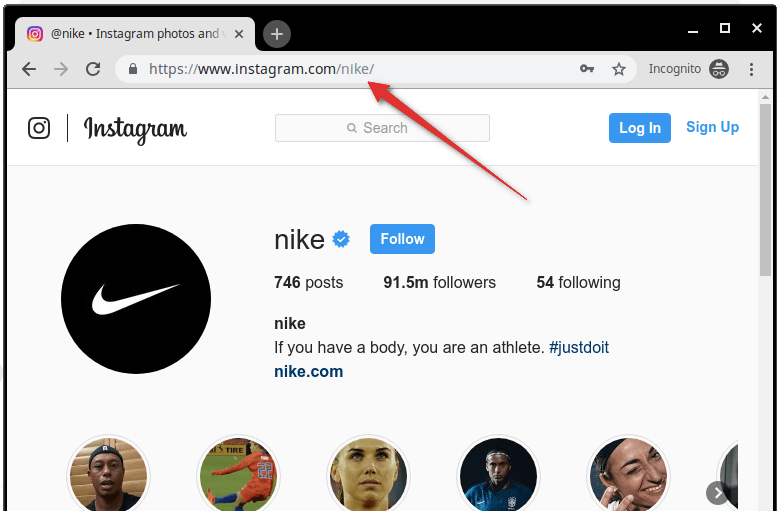

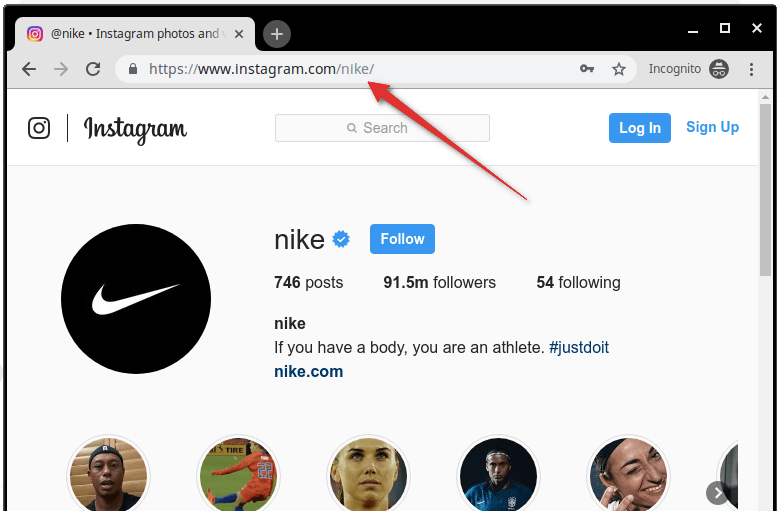

Marketing Tips3 days agoWhat is my Instagram URL? How to Find & Copy Address [Guide on Desktop or Mobile]

-

Business Imprint4 days ago

Business Imprint4 days agoAbout Apple Employee and Friends&Family Discount in 2024

-

App Development4 days ago

App Development4 days agoHow to Unlist your Phone Number from GetContact

-

News5 days ago

News5 days agoOpen-Source GPT-3/4 LLM Alternatives to Try in 2024

-

Crawling and Scraping5 days ago

Crawling and Scraping5 days agoComparison of Open Source Web Crawlers for Data Mining and Web Scraping: Pros&Cons

-

Grow Your Business3 days ago

Grow Your Business3 days agoBest Instagram-like Apps and their Features

-

Grow Your Business5 days ago

Grow Your Business5 days agoHow to Become a Prompt Engineer in 2024

-

Marketing Tips3 days ago

B2B Instagram Statistics in 2024