Business Imprint

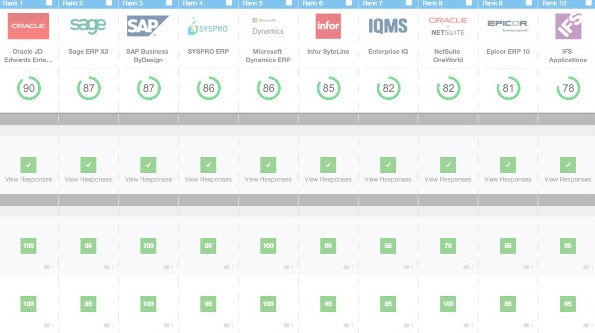

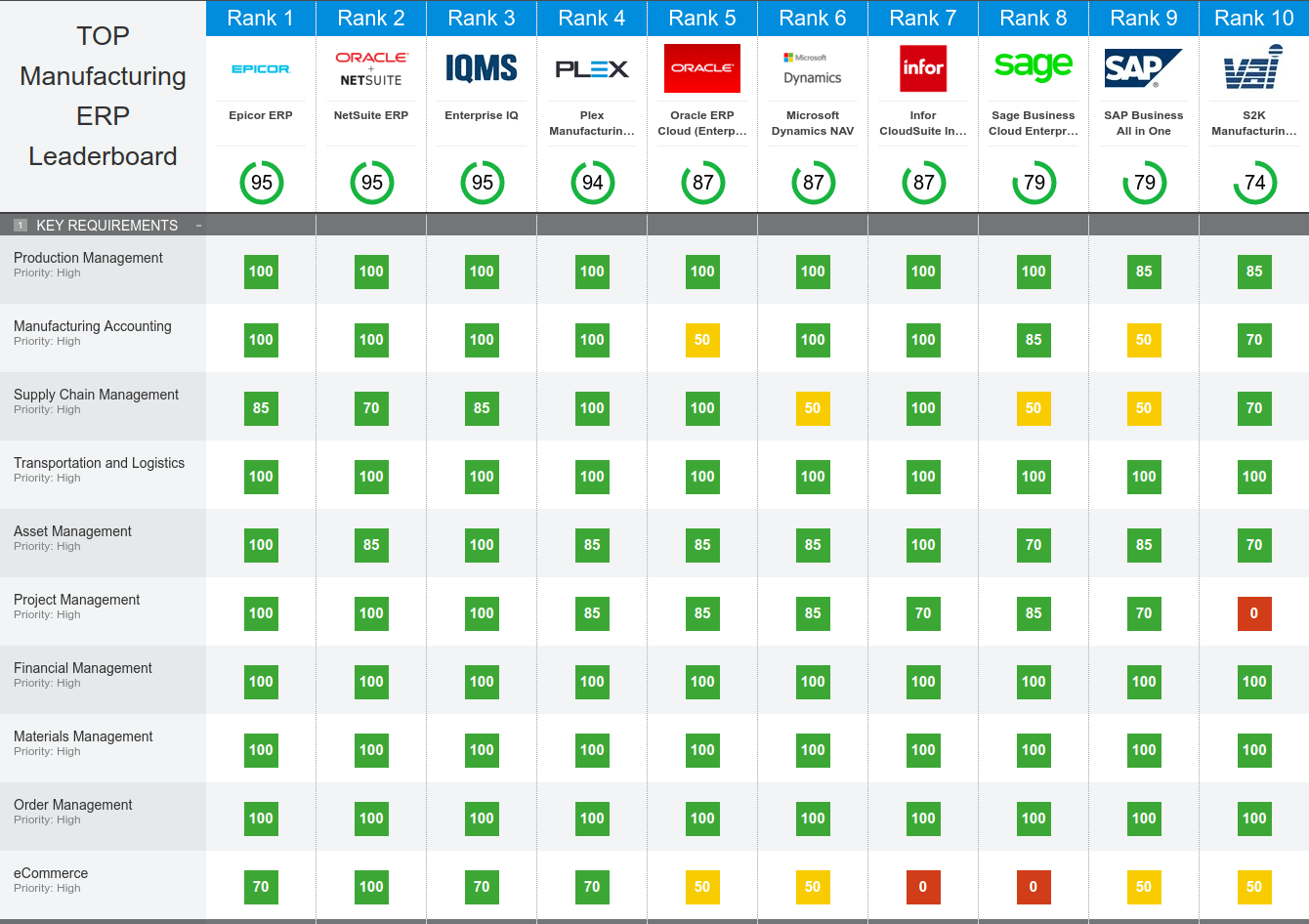

Top ERP for Manufacturing Reviews 2023

Top ERP for Manufacturing 2023 – Expert Reviews and Pricing – Free Analyst Report. Find the best ERP system for your business.

Top 10 Manufacturing Software Software Analyst Report 2023

“SelectHub provides an intelligent platform for informed software decision making.”

Jamie Cutler, CIO at PFB Energy

Top ERP Software Features Checklist

Key Insights. We’ll go into greater analysis for each feature but here’s a quick overview:

Most buyers need tools to manage parts of the supply chain, but few need end-to-end management.

ERP buyers care about their finances more than other software buyers.

Buyers don’t care about holding onto existing systems, except when it comes to accounting.

Top Features here:

Accounting

Accounting was by far the most requested feature for ERP buyers. Over 92 percent of respondents indicated they would like to see some accounting functions in their next ERP. Accounting’s position as the number one identified feature doesn’t come as much of a surprise.

Inventory

Inventory, while not as highly sought after as accounting, still raked in large numbers with 62 percent of respondents. Interestingly, of all the respondents who didn’t mention inventory as a key feature, not a single one mentioned keeping their standalone system (the way many did for accounting).

Manufacturing

This feature was third most requested at 43 percent. Of the respondents who identified manufacturing, over 40 percent of them went further and identified materials requirements planning as a need. Additionally, 49 percent of them identified a manufacturing execution system as something they would like to have.

Finally, 22 percent of those who needed manufacturing capacity specifically mentioned needing a Bill of Materials (BOM) as well. Interestingly, 3.5 percent of respondents across the entire survey wanted a BOM feature but didn’t mention desiring any other manufacturing components.

Customer Relationship Management

This was an interesting topic for a couple reasons. While it was listed as a key feature by buyers 38 percent of the time, it was concurrently referred to as a “nice-to-have” quite often. And less than one percent of buyers specifically mentioned wanting to integrate their current CRM into their next ERP. With this, we can conclude CRM is a lower priority, even for the buyers who identified it.

When anyone elaborated on their need for a CRM, they typically discussed automated marketing and lead tracking. One respondent said he needed an ERP with a CRM module because it took too much time to enter a customer’s information into each of his disconnected software systems.

Human Resources

An HR module was the fifth most requested feature at 26%. Most respondents just listed “HR” but a handful mentioned capabilities like recruiting, payroll, employee training and self-service portals. See our recent survey on HR for more in-depth results.

Warehouse Management

Just under 24 percent of respondents named warehousing as a key feature. Most respondents left it at that but a few elaborated for us. Only 3.6 percent of all respondents named “pick, pack and ship” as a feature the would like to see and 3.3 percent said they wanted traceability.

Business Intelligence

Overall, 20 percent of those surveyed wanted at least some BI capabilities.

Other

Other notably requested features included barcoding at 7.6 percent, project management at 6.4 percent and mobile capabilities at 5.6 percent.

The Top 10 Reasons Companies Choose Process Manufacturing ERP

While they may vary somewhat depending on industry or company size, the following are the most common reasons process manufacturers choose ERP solutions specifically designed for their needs:

1. Quality Management

Quality management is critical for process manufacturers in order to comply with a plethora of laws and regulations, which can vary depending on where the products are made and where they are sold. An ERP solution helps process manufacturers avoid recalls or legal issues that can be caused by a lack of compliance with safety laws or industry standards.

2. Supply Chain Optimization

Supply chain optimization is important for process manufacturers for multiple reasons. First, in order to provide good products at reasonable prices, process manufacturers need to purchase ingredients and raw materials from reliable suppliers. They also need to create long-term relationships with these suppliers. ERP solutions help process manufacturers track performance, costs, transaction history, and other capabilities needed for effective and efficient supplier management.

3. Recipes and Formulas

Recipes and formulas in process manufacturing are not only complex, but they also usually don’t leave much room for error. A minor change in quantity for one ingredient can lead to the quality management issues mentioned above, or even compromise an entire production batch. While defective production batches may be adjusted to improve their quality, this process can be very complex, since manufacturers need to take into account all the possible chemical reactions generated by adding ingredients that were not part of the original recipe.

4. Tracked Costs and Profitability

The complexity of the recipes or formulas makes cost tracking a challenge for process manufacturers. Ideally, they should track the cost of every ingredient based on the quantity used and its chemical characteristics, such as potency. Furthermore, the cost of wasted raw materials and ingredients also needs to be tracked as accurately as possible. Without all these details, process manufacturers cannot estimate their total actual costs per unit or compare this with the sales price to determine profit margins.

5. Adaptation to Different Types of Markets

Either because of local regulations or to adapt to a local market, process manufacturers may need to create and use formulas and recipes that are specific to the markets they serve. For example, a recent trend forcing food and drinks manufacturers to adjust their recipes is increasing pressure to reduce the amount of sugar in soft drinks. Even some of the largest manufacturers like Coca-Cola are changing their products so that the amount of sugar and calories is reduced.

6. Reduced Waste

Since creating perfect recipes or formulas is almost impossible in process manufacturing, there will always be a percentage of the final output that is wasted. Waste can also happen when manufacturers change their recipes to adapt to shifts in demand or to address shortages in ingredients or raw materials. While it’s very difficult to eliminate waste, process manufacturers can use ERP systems to calculate an estimated level of waste, track the actual waste, and compare the two in order to improve efficiency in production operations.

7. Agile Production

Process manufacturers rarely focus exclusively on one or a few products. They usually manufacture multiple products, oftentimes producing multiple variations of each product. Since each product has a different recipe and may require different production operations and equipment, it can be extremely complicated to transition between production cycles. In order to increase productivity and avoid the underutilization of their equipment, manufacturers need to be able to plan ahead and adjust planning when needed.

8. Improved Product Development and Go-To-Market Strategies

While product development is mostly managed using product lifecycle management (PLM) software, ERP for process manufacturers contains valuable data that can be used to create new products and improve existing ones. One example is historical information about sales volumes, returns, and customer satisfaction. This can help manufacturers understand which products are successful and which aren’t.

9. Responsiveness to Consumer Pressure to be More Environmentally Conscious

Consumers nowadays have higher expectations than ever, and one of these expectations is for manufacturers to be more environmentally conscious. Due to the use of chemical substances, process manufacturers are more likely to pollute the environment than most other industries. Even though manufacturers cannot completely eliminate the negative effects they have on the environment, consumers expect them to make an effort to reduce emissions and produce relatively clean products.

10. Increased Competitiveness

All of the reasons mentioned above help process manufacturers become more competitive in their market. Nowadays, process manufacturers need to be compliant with quality standards, capable of adapting to changing customer demand, transparent and environmentally conscious, all while keeping costs and waste low in order to be profitable.

When evaluating process manufacturing ERP, buyers are facing a few major challenges that are specific to this type of software. One of them is the fact that some vendors have adapted their discrete ERP solutions for process manufacturing, which can make their offerings too generic for some industries. Large process manufacturers also need to evaluate the integration between ERP and other solutions that are critical for their business, like PLM or MES.

Even though some vendors provide their own PLM solutions for process manufacturing, such as Oracle, the functionality offered by these solutions may not be enough for some manufacturers. In this case, a tight integration between ERP and the most robust PLM solutions in the market may be the best alternative.

What is not an Advantage of ERP?

First up, let’s look at the main reasons why businesses choose to use ERP. There are several more advantages to using ERP than disadvantages (if there weren’t, who would use it?). Below are several of the biggest advantages of using ERP software for your business needs:

Lower IT Costs

One simple reason to do an ERP implementation is to lower IT costs and improve efficiency. Having a unified ERP system can greatly lower IT-related expenses, including management/administration staff, support, infrastructure needs, and application licensing. Using a single system also reduces training requirements for end-users, since they only need to learn one system rather than interacting with numerous individual applications.

Total Visibility

ERP allows total access to every important process in your business by making data from every department easily accessible to you and your senior management. For example, you can monitor inventory levels on a daily basis, including future consignments that are yet to be received and inventory that’s currently in transit. By knowing precisely where you stand regarding inventory levels, you can control your working capital on a more precise level and more easily adhere to the strategy that you’ve developed for the long-term success of your business.

Improved Reporting and Planning

Implementing an ERP suite across departments means your organization has a single, unified reporting system for every process. By having a single source of information, an ERP system can readily generate useful reports and analytics at any time. This software gives you the ability to analyze and compare functions across departments, without the hassle of multiple spreadsheets and emails. One of the most popular reports involve finances (go figure). Standard financial reports such as income and cash flow statements generally are built-in, and custom reports can be quickly generated by users without IT intervention.

Complete Customization

One of the biggest advantages of ERP software is its modular makeup. Most ERP vendors offer multiple platforms, and each one contains several applications that can be implemented according to business needs. Each application is designed to be able to stand alone or integrate with the suite, so your company can pick and choose which components work best. This means that businesses are able to craft an interface tailored to their company’s needs. Most ERP implementations are designed with the ability to seamlessly integrate into the full suite or to be used as a standalone module.

Improved Efficiency

Along with reduced IT & training costs, an ERP can reduce the time and effort required by your workforce to carry out their daily activities. Properly implemented, an ERP can greatly reduce or eliminate repetitive manual processes, thus freeing up team members to focus on revenue-affecting tasks. The system likewise can aid in the adoption and enforcement of industry best-practice processes, lending familiarity to all actions across the enterprise.

Customer Service

Your company’s clients also receive benefits from the utilization of an ERP system, even if they don’t know it. Because client information is centralized and streamlined, your sales team will be able to focus on building and maintaining customer relationships, both domestically and globally. Most up-to-date ERP suites also support e-commerce integration. This means your business will be better able to handle web-based order processing and client interactions.

Data Security

One of the biggest advantages of an ERP system is data security. After all, at the heart of the ERP concept is data. Sharing data across functional silos such as Customer Service, Sales, Marketing, and Business Development enhances collaboration throughout a company. The other side to widespread data access is controlling who can see and edit the information. ERP solutions have intrinsic controls to ensure the security of your data. Since all of your company’s data is managed through the cloud, they employ round-the-clock security experts to ensure their servers are protected.

Improved Collaboration and Workflows

A lot of progress can be made through collaboration. However, people aren’t going to go out of their way to collaborate. An ERP platform simplifies the process of collaborating with others by providing employees with access to the data they need when they need it. They do this by providing simple interdepartmental collaboration, where information from each department is funneled into one centralized location. This allows for real-time project updates and better communication across the whole company.

Deep Integration

Most ERP vendors offer additional services for further integration of your business. A few examples include:

E-commerce integration packages for web-based ordering

Application Programming Interface systems that allow peripheral systems, like barcode readers, to be integrated into your existing system

Business Intelligence functions that identify potential problem areas throughout the business

Improved Data Quality

When compared to manual data processes and other approaches, ERP systems’ data quality represents a drastic improvement.

Improved Data Accessibility

You can’t hope to operate an efficient and successful business without impeccable data control. It’s crucial for the right people to be able to access the right data at the right time, and it’s equally important to prevent certain users from accessing certain types of information. ERP systems include advance access control and user management features that allow you to manage everything down to the finest detail. At the same time, they provide for easier access when it’s needed through support for mobile devices and the cloud.

Standardized Business Processes

Most ERP systems are developed according to industry best practices and proven business processes. These tried-and-true processes bring major benefits to the table for businesses of all sizes. It also allows businesses to standardize their own processes and systems, which further enhances productivity and efficiency. These processes deliver consistent results that allow you to continually improve the way in which you operate your organization.

Facilitated Regulatory Compliance

One of the most difficult things for businesses to do is consistently assure they’re meeting compliance requirements. ERPs aid in regulatory compliance by virtue of secure and validated data, combined with built-in reports. Just as important is that this reduces the amount of effort it takes to meet compliance requirements.

Improved Supply Chain Management

For companies that deal with the moving of physical inventory and production, an ERP system bolsters supply chain management in a variety of ways. This improvement results in shortened lead times, improved on-time deliveries and many other benefits that enhance the overall operation and success of your business.

Superior Scalability

To ensure the ongoing success of your business, you have to keep an eye on the future. All too often, businesses fail to plan properly and experience serious growing pains that pose serious roadblocks to whatever progress they’re enjoying. Having a system in place that can elegantly and efficiently accommodate your company’s growth is of the utmost importance, and the right ERP system makes it easy.

ERP Disadvantages

Direct Cost

This is by far the biggest disadvantage to ERP software. The up-front cost of the entire implementation process can be prohibitively high, especially for small-to-medium-sized businesses. This includes the full process of planning, testing, configuring and customizing the software as well as the cost of actual implementation.

Indirect Cost

Financial cost is not the only associated expense with ERP implementation. Businesses must also take into account the opportunity cost of manpower and time necessary for a successful deployment. Planning out a realistic timetable will give you a better idea of whether or not the cost is worth it for your company.

Customization

While this is a potential advantage, it can just as easily become a disadvantage if handled incorrectly. This blog post by expert ERP consultant Eric Kimberling outlines potential problems as well as tips for avoiding the pitfalls of both over-customization and under-customization.

In summary, when making a decision about which platform is right for your business, it’s important to consider potential disadvantages as well as advantages. Experts like Mr. Kimberling recommend making an honest assessment of your organization’s needs and problem areas and then seeking out an ERP system that will give your business the most potential to improve.

ERP System Examples for ERP Software Platforms

Learn more about what functionality is available in different ERP system examples and evaluate which might be best for your corporation.

Epicor ERP 10

Epicor’s flexible collection of ERP tools can be deployed on company computers, in the cloud or on an external server. This platform highlights collaboration by allowing users to access data from different devices. A 2014 Forrestor Consulting Study found that this software gave companies a 103 percent return on investment within about a year and a half.

IFS Full Suite ERP

If you’re looking for a user-friendly interface for project management, the IFS Full Suite ERP solution is ideal. This platform is perfect for manufacturing and engineering companies.

Infor ERP SyteLine

Based in the cloud, this ERP solution can be customized for large-scale manufacturers and distributors. It’s scalable, so it easily adapts as your business grows.

Microsoft Dynamics AX 2012

International businesses will find Microsoft’s ERP solution useful for most of their departments. The software is powerful and easy to implement, improving its value for driving organization and productivity.

Oracle JD Edwards EnterpriseOne

Oracle’s most recent product is ideal for corporations seeking a financially focused ERP solution. This ERP automates a majority of a company’s accounting, whether for small projects or overall evaluation. EnterpriseOne helps businesses amplify their financial success.

Sage ERP X3

For small-to-mid sized companies, Sage ERP X3 improves productivity within fundamental business systems. The software has a complete mobile capability, making it ideal for use in a flexible corporate environment.

SAP Business ByDesign

Another cloud-based ERP tool, SAP Business ByDesign can manage any facet of a corporation with around-the-clock availability.

SYSPRO 7

Completely customizable, SYSPRO 7 can be incorporated into any company’s system management. Whether your needs are based on financials, customer service, sales, distribution or manufacturing, you can personalize SYSPRO 7 for your company.

Manufacturing companies have different needs than consulting firms. Businesses that focus on retail require distinct capabilities than those in the financial sector.

-

News21 hours ago

News21 hours agoOpen-Source GPT-3/4 LLM Alternatives to Try in 2024

-

Crawling and Scraping21 hours ago

Crawling and Scraping21 hours agoComparison of Open Source Web Crawlers for Data Mining and Web Scraping: Pros&Cons

-

Grow Your Business21 hours ago

Grow Your Business21 hours agoHow to Become a Prompt Engineer in 2024

-

Software Development21 hours ago

Software Development21 hours agoWhy is the Julia Programming Language Popular in 2024?

-

Business Imprint24 hours ago

How the Digital Yuan Is Reshaping Consumer Banking Behaviors

-

Business Imprint24 hours ago

Business Imprint24 hours agoThe Future of Finance: Investing in Bitcoin for Long-Term Wealth