Business Imprint

Exploring the House of Lean Manufacturing

What is the House of Lean exactly?

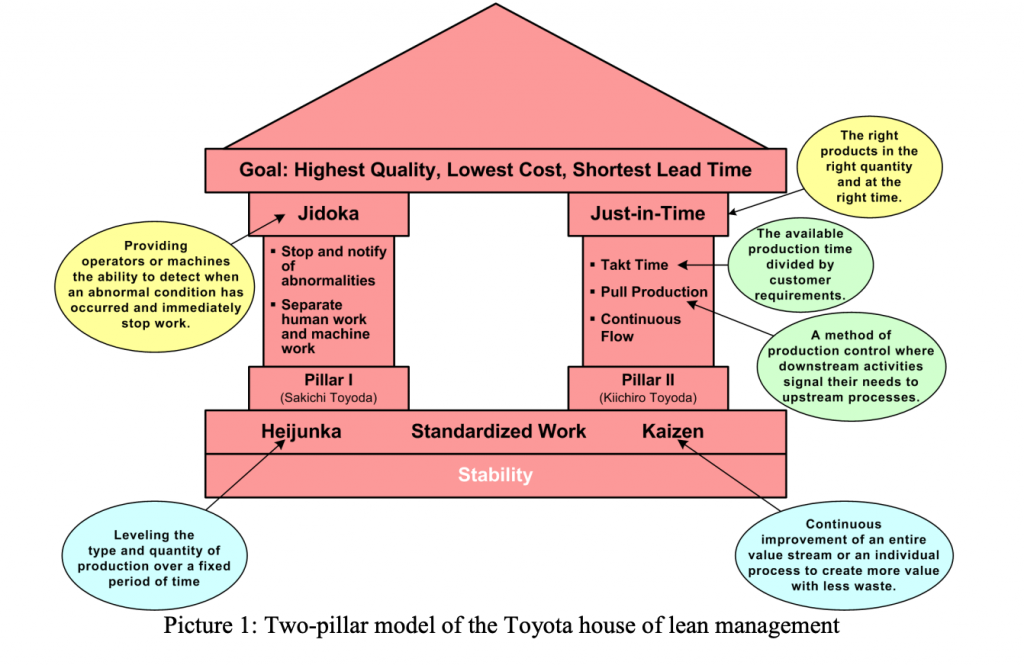

The House of Lean depicts how Lean is implemented in organizations. It depicts the Lean method as a house that works together to achieve desired goals. House of Lean, as the name implies, is anchored in the principles, strategies and concepts of Lean manufacturing.

This graphic guides organizations to optimize their manufacturing and operations with the Lean method. It is focused on solving problems and continually improving through innovative principles. Learn more about this method in the sections that follow.

There’s three major problems with any production system:

- Waste (Muda)

- Instability

- Variability (Mura).

These problems can negatively impact your company’s efficiency, increasing costs, and increasing delivery times. This can lead to a lower Return On Investment (ROI), which will negatively impact your business’s efficiency. Lean Manufacturing House was created by the founders to symbolize the Lean principles and their coexistence.

Stability is the foundation of Lean Manufacturing House.

This refers to team stability and standardized work methods. It can also be applied to a production process. The foundation of the house is made up of two elements: (1) Reduction in muda (wastes), and (2) Kaizen – Continuous Improvement. These are the 2 pillars of Lean Manufacturing house JIT, and JIDOKA.

- Heijunka: Linear and sequenced production.

- Standardized work: Reduced variability in work processes: A system that manages sudden demand fluctuations as they happen.

The following tools are used to support the roof of the house’s walls:

- The JIT pillar: Pulled, Takt time, and continuous flow.

- The Jidoka Pillar: Man-machine Separation (one operator can manage several machines) or Automation (one operator can manage several machines).

- The Lean Manufacturing Method’s roof is described by CQD. It reduces production cost and improves quality. It also matches delivery time to customer requirements.

If the foundations are first built, then Lean Manufacturing House will only grow. Ecoflex is a tool to implement the Kaizen philosophy and act as a catalyst in the reduction of waste and continuous improvement. Only a flexible, modular system such as Ecoflex can offer a production system that allows for the next steps in Lean Manufacturing: work standardization, sequencing (Heijunka), JIT or JIDOKA.

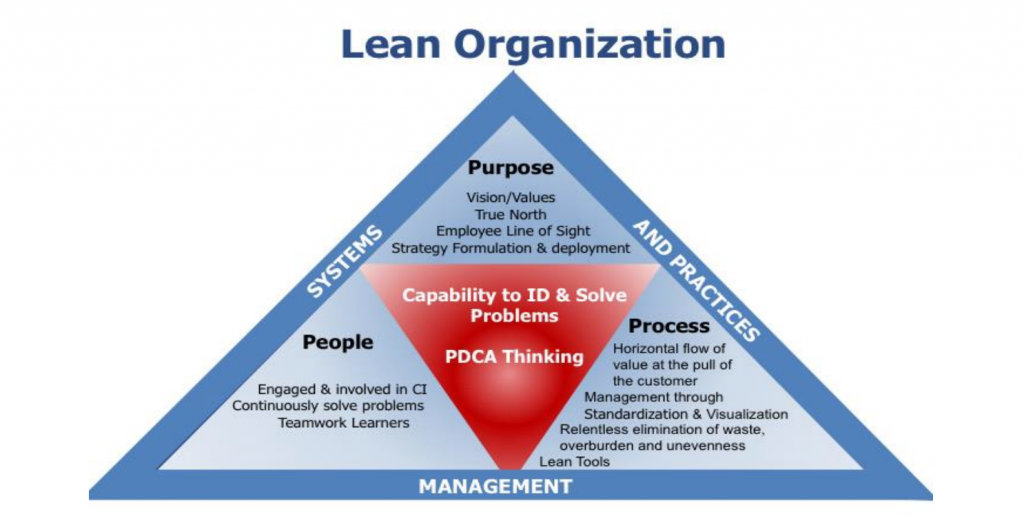

Toyota House is a lean transformation model

All of us are trying to change. At the company level a transformation is a big experiment, at process level, it is a daily-hourly-immediate work itself. To transform the way people think and behave within an organization to be more of a problem-solving mindset is no easy task and varies from industry-to-industry, company-to-company, person-to-person. It takes discipline, investment, and the belief that things can be improved. This is the process of turning an organization into a lean one. This transformation is described in the lean management community through the lean transformation models.

They are illustrated using the Toyota house example. Picture 4 and 5 show two of these models. They are basically the same model, except that they came from different institutions. Model in Picture 1 was designed by the Lean Enterprise Institute in the USA, while Model in Picture 2 was designed by Lean Enterprise Academy in Great Britain. These models represent the most recent version of Toyota houses, and the latest understanding of lean organizations based on the situational approach.

It seems to me that this is rather a successful PR. And in any healthy company, these principles take place. Maybe not everyone declares it. But they publish books.

Conclusion

While there will be other Toyota house models in the future, the current model with a situational approach will still be valid. To keep up with the current times, it is essential that all employees are aware of the latest versions. When implementing the model, it is likely that modifications are required to suit the specific circumstances of each organization. While the prescriptive approach is still valid for concepts, methods and tools, it is changing how they are implemented.

-

Marketing Tips2 days ago

Marketing Tips2 days agoWhat is my Instagram URL? How to Find & Copy Address [Guide on Desktop or Mobile]

-

Business Imprint3 days ago

Business Imprint3 days agoAbout Apple Employee and Friends&Family Discount in 2024

-

App Development3 days ago

App Development3 days agoHow to Unlist your Phone Number from GetContact

-

News4 days ago

News4 days agoOpen-Source GPT-3/4 LLM Alternatives to Try in 2024

-

Crawling and Scraping4 days ago

Crawling and Scraping4 days agoComparison of Open Source Web Crawlers for Data Mining and Web Scraping: Pros&Cons

-

Grow Your Business2 days ago

Grow Your Business2 days agoBest Instagram-like Apps and their Features

-

Grow Your Business4 days ago

Grow Your Business4 days agoHow to Become a Prompt Engineer in 2024

-

Marketing Tips2 days ago

B2B Instagram Statistics in 2024